3-D–Printable Material Purifies Biogas At Low Cost

07/10/2020 Biogas released from decomposing organic matter is about 60% methane, making it a valuable renewable source of natural gas. But carbon dioxide, which makes up the other 40%, must be removed before the biogas can be turned into fuel. Many of the existing methods for removing the CO2 and other impurities are too expensive or impractical for small-scale biogas sources, like manure digesters on dairy farms. Now, researchers have addressed this need by developing a new low-cost sorbent made from two familiar compounds: sodium carbonate (also known as washing soda) and silicone (Environ. Sci. Technol. 2020, DOI: 10.1021/acs.est.0c01755).

Biogas released from decomposing organic matter is about 60% methane, making it a valuable renewable source of natural gas. But carbon dioxide, which makes up the other 40%, must be removed before the biogas can be turned into fuel. Many of the existing methods for removing the CO2 and other impurities are too expensive or impractical for small-scale biogas sources, like manure digesters on dairy farms. Now, researchers have addressed this need by developing a new low-cost sorbent made from two familiar compounds: sodium carbonate (also known as washing soda) and silicone (Environ. Sci. Technol. 2020, DOI: 10.1021/acs.est.0c01755).Although biogas is already being produced as a waste product of industrial and agricultural processes, few of the thousands of small-scale operations in the US are able to invest in turning this waste into renewable fuel. Other CO2-removal methods such as water scrubbing and cryogenic separation are too expensive for these smaller biogas sources. Sarah E. Baker and her group at Lawrence Livermore National Laboratory sought to fill that gap.

About 5 years ago, Baker and colleagues reported that microcapsules of a sodium carbonate solution encapsulated by silicone—a highly gas-permeable material—could absorb CO2 very efficiently, as the CO2 reacts with the basic sodium carbonate solution to form bicarbonate (Nat. Commun. 2015, DOI: 10.1038/ncomms7124). But the microcapsules, resembling small fish eggs, couldn’t easily be made in large quantities.

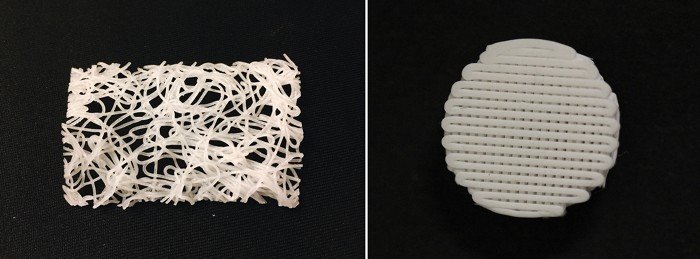

Now, her team at Lawrence Livermore made the sorbent into a composite by blending sodium carbonate powder and silicone resin together. The researchers then extruded the material like spaghetti into mats or 3-D printed it into porous sponges with a high surface area. After curing the material, the team soaked the structures in water to hydrate the sodium carbonate and prime it for CO2 absorption.

Tests showed that the material produced a 99% pure stream of methane from biogas collected from a wastewater treatment plant until the material became saturated with CO2. The material could be regenerated with a low-energy air stripping process, adding to its efficiency.

The material is low cost, water tolerant, and nontoxic, and it can absorb CO2 at near-ambient pressures and temperatures, which means the process uses relatively little energy, says study lead author Maxwell Murialdo.

Baker and colleagues estimate that this biogas scrubbing method would cost $700–$1,600 per m3·hr, much less than water scrubbing which costs $2,700–$3,100 per m3·hr.

“You need a lot of surface area whenever you’re trying to separate gas by reaction,” says Alissa Park, a chemical engineer at Columbia University. “By printing this material with high resolution, they can create a lot of these internal kinds of surfaces, which reduces the need for high pressure in the system and makes it much more efficient.”

Now that the material has proven to be effective and economical, the team has partnered with Southern California Gas Company to make larger prototype devices out of the sorbent and test them in the field. SoCal Gas is a natural gas utility that serves more than 21 million people.

Source: https://bit.ly/33AGRg5, via Chemical & Engineering News