A New Way To Make Nanoscale Lenses

27/01/2021 Nanoscale optical components, such as lenses and waveguides, are used in imaging and computing platforms. Yet it’s challenging to make these components with more than one refractive index—a property that describes how light bends as it passes through the material—though multiple indices are needed in devices that focus light in specialized patterns. A research team led by Lynford Goddard and Paul Braun of the University of Illinois at Urbana-Champaign has designed a new technique for making nanoscale optical components that feature a gradient of refractive indices (Light: Sci. Appl. 2020, DOI: 10.1038/s41377-020-00431-3).

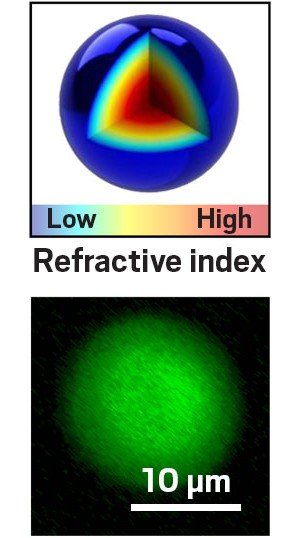

A research team led by Lynford Goddard and Paul Braun of the University of Illinois at Urbana-Champaign has designed a new technique for making nanoscale optical components that feature a gradient of refractive indices (Light: Sci. Appl. 2020, DOI: 10.1038/s41377-020-00431-3).To make the components, the researchers fill the voids of a porous silicon wafer with a photosensitive monomer called IP-Dip. By varying the intensity of light emitted from a laser, they can tune the amount of polymer formed in the voids; more polymer results in a higher refractive index. This method allowed the team to build nanoscale optical components, such as lenses of various geometries. Their list includes the world’s smallest spherical Luneburg lens—only 15 μm in diameter—whose 3-D refractive index gradient allows it to focus an incoming beam of visible light onto a single point on the sphere’s opposite surface, Goddard says.

Sharon Weiss, an electrical engineer at Vanderbilt University, says the ability to control the material’s refractive index and shape in three dimensions “lays the foundation for a lot of exciting future research avenues,” including the construction of multicomponent arrays.

While this method has applications in photonics, Braun says the innovation was made possible only thanks to advances in chemistry and materials science.

Source: https://bit.ly/3a5PGk9, via Chemical & Engineering News.