Electroplating method makes conductive nanostraws for injecting into and sampling from cells

09/05/2023

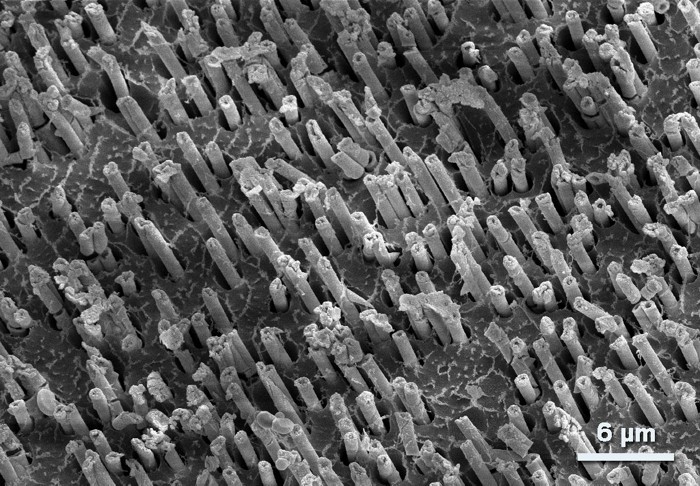

Credit: ACS Appl. Mater. Interfaces

Hollow nanosized needles, or nanostraws, are a promising tool for opening up tiny, temporary holes in cell membranes to deliver molecules or sample a cell’s contents. Nanostraws could also deliver gene editors into cells for immunotherapy, cutting the need to use costly viruses for the job. But making nanostraws requires expensive manufacturing equipment in a clean room facility, and using nanostraws often requires applying a high voltage in order to open up the cell membrane. Now, researchers have developed a more affordable fabrication approach that can be done in an ordinary lab. What’s more, the new nanostraws are conductive, thus lowering the amount of voltage needed to levels less likely to damage cells (ACS Appl. Mater. Interfaces 2019, DOI: 10.1021/acsami.9b15619).

Researchers made earlier iterations of nanostraws with atomic layer deposition (ALD), which grows thin films of materials such as metal oxides one layer of atoms at a time. In their new approach, Xi Xie of Sun Yat-Sen University and colleagues replaced ALD with electroplating, a simple process which uses an electrical potential to deposit ions in a solution onto a surface.

They first sputtered a thin layer of gold on the bottom surface of a polycarbonate template containing an array of pores in order to make a conductive base layer. Then they electroplated platinum, gold, or the conductive polymer poly(3,4-ethylenedioxythiophene)—three common materials used in electrophysiology studies—from the top. The materials lined the pores of the template, creating the hollow nanostraws. The team then used mechanical polishing and oxygen plasma etching to remove the polycarbonate template, revealing an array of vertical nanostraws, each a few hundred nanometers in diameter. According to Xie, their method can work with templates of various pore sizes or pore densities, or with other plating materials.

Ciro Chiappini, a nanomedicine researcher at King’s College London, says this study is “a needed and significant step” toward developing affordable nanostraws.

Credit: ACS Appl. Mater. Interfaces

An electroplating method fabricates conductive nanostraws that can be used to get molecules into or out of cells. A metal or conductive polymer (yellow) is deposited onto a polycarbonate template (gray), which is etched away to leave behind the nanostraws.

Using a representative platinum nanostraw array, Xie and colleagues demonstrated that they could deliver a fluorescent dye into cultured human cells and extract intracellular materials to examine how the levels of an enzyme changed over time.

The conductivity of the new nanostraws allowed the researchers to open tiny pores in the cell membrane by applying a voltage of only 3–5 V, a safer range for cells compared with 10–20 V needed when using nonconductive nanostraws.

These straws could make cellular treatments such as CAR-T therapy faster, safer, and cheaper, says Nicholas A. Melosh, a materials scientist at Stanford University who has done nanostraw research. Typical immunotherapy delivers therapy to a patient’s immune cells using viruses, which is costly and carries the risk of dangerous immune responses once the cells are put back into the patient, he says. Nanostraws could potentially deliver the necessary therapies to cells without the need for viruses.

Source: https://bit.ly/41JUwgG via Chemical & Engineering News